Start Reloading

Why Reload?

Why reload? If you are looking into reloading, you are most likely looking to either save money or perfect your long-range accuracy. When most people think reloading, they think about long hours of work just to save a few cents per round. For many reloaders that is exactly what it is but there are also many more benefits that seem to fly under the radar. Reloading opens a whole new world of shooting potential. From expanding your caliber range to being prepared for ammunition supply shortages, there are many perks to joining the ranks of the reloaders.

The greatest draw to reloading for most people if the potential cost savings. While there is an initial investment it can be easily offset after a few reloading sessions. Most people plan on saving money while still being able to shoot but just end up shooting more because of reloading (which isn’t a bad thing). The average cost saving per round reloading is about 50% depending on the caliber so you can very quickly recoup the costs of you reloading equipment. Along with the financial benefits of reloading comes the ability to increase your range, and I am not talking about your shooting distance. I am talking about caliber range. Most people shoot common calibers because of the ease of access to ammunition. Being able to purchase and reuse components allows you to consistently shoot harder to find or more specialty rounds.

At the end of the day ammo is a driving factor in shooting and sometimes there are shortages. In the current climate we are seeing extreme ammo shortages across the world which means finding common calibers can be very difficult. Reloading is a great way to supply yourself with ammunition even through harder times. Having the skills and equipment needed to reload is a timeless hobby that will only increase your footprint in the hobby.

Case Processing

Case processing is a very important step in successful reloading. While there are many procedures involved in case prep, here are some important basics that should be considered. Case cleaning, trimming, post-trim deburring, and primer pocket cleaning are all very essential in the case prep process. In order to produce top quality reloads, you’ll want to ensure that the case is free of dirt and debris and that it is sized correctly. You must also remove the primer (usually done during the sizing operation) and ensure that the primer pocket is ready to have a new primer seated.

A dull looking case is of no consequence. A dirty case, however, may reduce reload quality. A dirty case is more difficult to resize and may scratch reloading dies and/or chambers requiring premature die or firearm replacement. Cases can be cleaned in several ways. Case tumblers, either vibratory or rotary can make some mighty dirty brass look like new. Case tumblers are available to fit almost every budget and case volume need. Ultrasonic cleaners also do a great job and will clean out primer pockets as well as the inside of the case.

Cases stretch when they are fired, particularly bottleneck rifle cases. Case bodies are often shortened when resized, but their necks tend to stretch during this process. After a single firing and sizing, a case may stretch past the point of being suitable for reloading. Under some circumstances, a case may be reloaded and fired four or five times before its length exceeds the maximum allowable dimension. In any event, there will often be a point at which the case must be trimmed back to a workable dimension before it can be reloaded. Handgun cases seldom stretch like rifle cases; however, trimming may still be required in order to make them all a uniform length. Trimmers require the use of a pilot of appropriate caliber to keep cases positively aligned during the trimming process. Some case trimmers require the use of an appropriate shell holder. Precise case length is critical to uniform crimps and consistent neck tension, leading to better accuracy and smooth, reliable functioning.

During trimming, burrs form on the inside and outside of the case mouth. A deburring tool quickly gets the case smooth and ready for reloading. Cases should be deburred for the first reloading, especially inside the case mouth, even if they are not trimmed. After decapping, inspection of the primer pocket will reveal a hard, crusty, black deposit. If allowed to build to excessive amounts, this deposit can interfere with uniform primer seating and thus cause inaccuracy. A high primer can also be a potential hazard. This deposit is easily removed with a few twists of a primer pocket cleaner.

As stated in the beginning of this article there are many different steps that need to be considered when processing brass. We’ve only scratched the surface here, but we hope this has given new reloaders an insight into what goes into becoming a successful reloader. If you would like a deeper dive into reloading and what it takes to take a spent piece of brass and turn it into an accurate round of ammunition be sure to check out our 50th Edition Reloading Handbook.

Reloading

Reloading is simply the act of reassembling a round using each of the 4 basic components; case, primer, powder and bullet. To convert these components into ammunition you are going to need a press, powder scale, dies, and a priming tool. While these are the physical tools you will need in order to complete the reloading process it is also very important that you use a reloading manual. This will ensure you are using the correct amount of power, correct type of powder, correct bullets, and so on. Once you have all have all these tools you are ready to start the loading process.

Your reloading press is the center piece of your reloading operation. While all the tools for reloading have a purpose, the press is what everything revolves around. This is the piece of equipment that does the heavy lifting for the rest of the process. There are many different styles of presses out there to choose from so you can match the type of shooter you are to the type of press you are looking for. For example, a single stage is a slower method of reloading, but it offers tighter tolerances for more precise reloading then a progressive press.

The amount of powder you need will vary from cartridge to cartridge. Things such as bullet weight, desired velocity, and powder type will all affect your charge weight. In order produce an accurate charge, you will need a good scale. While there are many different options for scales and measuring devices, ensuring you have confidence that you are accurately measuring your powder at a consistent rate is very important. A good scale, either digital or mechanical, is a very important part of your bench and failure to accurately measure your powder charge can be very dangerous.

Your press is essentially worthless without dies. Dies are the tools that you use to perform the individual functions during reloading. From sizing the brass to seating the bullet and crimping the neck, each die has a specific job. Each die set has three to four individual dies in it and die sets are caliber specific. For example, if you plan on reloading for a 223, you will need a complete set of dies just for that caliber.

In order to ignite the powder charge within the case you need a primer. Now some presses come with a priming mechanism attached to the press itself which may make it easier for you to complete all the functions of reloading on the press itself. For the presses that do not have this or for reloaders that prefer to hand prime, there are hand tools that allow you to prime off the press. No matter which method you prefer, priming your brass properly is a very important step to reloading and improperly seated primers may result in shooting malfunctions.

While this is just an introduction to some of the equipment and process needed when reloading ammunition, this is a great place to start. There are thousands of different tools and procedures for reloading. Ensuring you are well educated before you start is the best thing that you can do. It is a good idea to start off with a good reloading manual. These manuals not only provide you with load data but also with in depth reloading information. This article only gives a brief outline of what you need to get started reloading but we recommend you pick up a copy of our 50th Reloading Manual for a much more detailed explanation about reloading your own ammo.

Basic and Essential Loading Equipment

- Up-to-date Loading Manual

- Reloading press

- Shell holder

- Reloading die set of appropriate caliber

- Case lubricant*

- Case lubricant pad*

- Safety glasses (especially for priming)

- Priming unit

- Primer tray

- Powder scale (graduated in grains avoirdupois)

- Powder trickler

- Powder funnel

- Two loading blocks

- Dial indicating caliper (graduated in 0.001” increments)

- Case trimmer with pilot

- Deburring tool

*Note: items 5 and 6 are not required when using a carbide die with some handgun calibers

50th Reloading Handbook

Item #9816050

Reloading Manual

Remember that all data sources become obsolete. The ballistic characteristics of specific components can and do change over time. It is possible for a component to undergo a substantial change without a name change. Thus, data changes with the passage of time. Failing to keep your data and knowledge up to date can bring on serious consequences.

Data tables are only a part of the knowledge needed to assemble safe ammunition. Take the time to read all of the instructional material in each manual update. Then reread it from time to time as a refresher.

Brass-Smith® Victory Press™

Item #7726350

Reloading Press

The reloading press selected is the foundation for the loading bench. A good beginning is to select a single station press having a “O” shaped frame, such as the Brass-Smith® Victory Press. This type of tool offers precise alignment of dies and shell holder, as the die station hole and shell holder ram hole are machined in line. Such tools will generally offer a lifetime of use. Lesser priced reloading tools are available for the shooter on a tight budget.

It is often advantageous to purchase the reloading press as part of a packaged kit. Such kits include many of the essential items needed at a substantial savings when compared to buying each item individually.

Lyman Shellholders

Multiple Item #’s

Shell holder

The shell holder allows the cartridge case to be aligned with, pushed into, and withdrawn from the various dies. One shell holder may serve for several cartridges. For example, a 30-06 shell holder is also correct for use with calibers 22-250, 243, 25-06, 270, 308 and many others. Be sure to use the correct shell holder or the case rim may tear off during resizing. This will leave the case jammed in the die, a very difficult situation to correct, and one best handled by the die manufacturer. Use the Shell Holder chart by Lyman to make sure you have the right shell holders on your workbench. A must for anyone reloading their own ammo.

Lyman Die Sets

Multiple Item #’s

Reloading Die Set

A die set may consist of two, three, or four separate dies. The first die is a resizing die designed to return the fired and expanded case back to factory dimensions. This die also usually removes the fired primer. Without appropriate resizing, fired cases may fail to rechamber. For beginning, as well as most advanced efforts, we suggest the purchase of a full length resizing die set. Most die sets are caliber specific. When it comes to reloading your own ammo, shop Lyman’s reloading die sets for proper bullet resizing.

Note: For many straight walled handgun cartridges, the use of a carbide sizing die will eliminate the need to apply sizing lubricant to the case and to remove the lubricant after sizing. This is a great time saver and prevents jammed-in-the-die cases due to improper lubrication.

WARNING: Never attempt to resize a loaded round.

Sizing dies for bottleneck cases include a spindle mounted expanding button which opens the case neck to a dimension suitable to properly accept and hold the bullet. Straight walled cases must be neck expanded in a separate die. This means that all straight case die sets have an extra die.

The bullet seating die, seats the bullet to the correct depth (adjustable). When required it can also crimp cases to bullets. A crimp is necessary for ammo used in most revolvers and in guns with tubular magazines. Ammo for use in pump or semi-automatic rifles is also normally crimped. Some shooters find crimping to be more precise if done separately from bullet seating. Thus, an extra die is sometimes used. Most bullet seat/crimp dies use a roll crimp. However, taper crimp dies are used for reloading of cases which headspace from the case mouth.

Qwik Slick Case Lube

Item #7631298

Case Lubricant

For all reloading efforts (except when using a carbide die for straight walled handgun cartridges), cases need to be lubricated before resizing. Failure to do so will result in a case hopelessly jammed in the resizing die. Qwik Slick™ Case Lube allows you to spray an entire loading block of cases in seconds!

Case Lube Kit

Item #7631300

Case Lubricant Pad

The proper method of applying lubricant is to use a lubricating pad to transfer sizing lubricant to your cases. As an alternative to using a pad you may use a spray-on type of lube such as Lyman’s Quick Slick Case Lube. Improve your reloading process with the Case Lube Kit by Lyman. Order today!

E-ZEE Prime Hand Priming Tool

Item #7777810

Priming Unit

Priming units are also called priming punches, priming rams, or priming arms. Priming units are used for reloaders to achieve maximum accuracy. All loading presses are equipped with basic priming units that accomplish the task of seating new primers. With these, the primer is often seated as the sized case is withdrawn from the resizing die (or in the case of a straight walled case as it is withdrawn from the neck expanding die). However, it is suggested that the shooter interested in maximum primer seating uniformity will do best to replace such standard priming units with a Ram Prime system. Ram Prime units are mounted at the normal die station and can be adjusted to give a very uniform primer seating depth by using the press stroke stop as a means to control primer insertion depth. Other tools such as a hand priming tool can greatly increase the speed and comfort in which cases can be primed manually during handloading. It may be best however for a beginner to start with the Ram Prime die as only one primer at a time would be handled.

Primer Tray

Item #7728053

Primer Tray

A primer tray is used to orient all primers one side up so as to ensure that, as each one is picked up and placed into the primer post, it is correctly oriented. It will also help keep primers free from any contaminants.

Microtouch 1500

Item #7750700

Powder Scale

To ensure the precise amount of powder is placed into each case, each powder charge must be carefully weighed. A powder scale is also required for the correct adjustment of any accessory powder measure. No dangerous gun powder overfills or underfills with a Powder Scale by Lyman.

E-ZEE Flo

Item #7752477

Powder Trickler (aka Dribblers)

These make the job go quickly and accurately. The trickler adds powder, one granule at a time, to the scale pan in order to bring a propellant charge to exact weight. Lyman’s powder Trickler is the first trickler designed that works with any reloading scale, mechanical or electronic.

E-ZEE Powder Funnel

Item #7752431

Powder Funnel

Without a powder funnel there is no practical way to get propellant from the scale pan into the case. A simple but effective funnel will work with cases as small as 22 caliber and as large as 45 caliber. The Powder Funnel by Lyman is a great reloading tool to pour gunpowder into a case without spills.

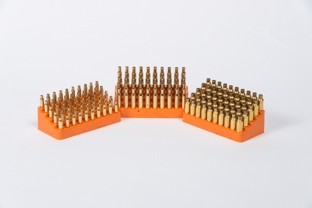

Bleacher Blocks

Item #7728087

Loading Blocks

Loading blocks hold the cases on the bench in an organized manner. Always use two loading blocks. Cases are picked up, a loading step performed and then they are placed in the second loading block (positioned on the opposite side of the loading tool). Lyman’s Bleacher Blocks are compact and sturdy for holding your cases during reloading operations.

Electronic Caliper

Item #7832218

Dial Indicating or Digital Caliper

This tool allows the reloader to accurately measure the depth of seated primers, to check case lengths before and after trimming, to maintain an appropriate cartridge overall length and to discover the source of many difficulties. Calipers are available as inexpensive plastic types or stainless steel models that sometimes outlast the reloader.

Lyman Universal Trimmer Power Pack Combo

Item #7862003

Case Trimmer

Cases stretch when they are fired. Case bodies are often shortened when resized but their necks tend to stretch during this process. After a single firing and sizing, a case may stretch past the point of being suitable for reloading. Under some circumstances, a case may be reloaded and fired four or five times before its length exceeds the maximum allowable dimension. In any event, there will always be a point at which the case must be trimmed back to a workable dimension before it can be reloaded. Trimmers require the use of a pilot of appropriate caliber to keep cases positively aligned during the trimming process. Some case trimmers require the use of an appropriate shell holder. Precise case length is critical to accuracy and smooth, reliable functioning. Lyman has the broadest selection of trimming tools in reloading.

Deburring Tool

Item #7810199

Deburring Tool

During trimming, burrs form on the inside and outside of the case mouth. A deburring tool quickly gets the case smooth and ready for reloading. Cases should be deburred for the first reloading, especially inside the case mouth, even if they are not trimmed.

The cost of getting set up with the necessary essential tools will vary depending on where the equipment is purchased and exactly what model tools are selected. The return on the initial investment can be rapid or slow depending upon how often you shoot.

You will require a supply of primers, powder and bullets to begin reloading. The cost of these will vary dependent upon the caliber and the type of ammunition you want to assemble.

Additional Accessories

There will come a time when you may wish to add to your basic reloading tools. Accessory items can help improve accuracy, save on ammunition costs, or make the loading process faster. Some of the more useful accessories include the following:

1. Powder Measure And Optional Stand

No. 55 Powder Measure

Item #7767783

A powder measure allows the reloader to dispense a near exact powder charge rapidly. Because charges thrown from a measure will vary, gun powder measures must be used in conjunction with a scale. To do so, adjust the measure to throw a charge slightly below the desired weight. Set the measure so that no individual charge will be over the desired weight - it is irritating to try to remove excess propellant from the scale pan. Then, meter a charge directly onto the scale pan. Return the pan to the scale and bring the charge into exact balance by adding the last few granules of powder with a powder trickler for accurate measurements.

Primer Pocket Cleaner

Item #7777790

2. Primer Pocket Cleaner

After decapping, inspection of the primer pocket will reveal a hard, crusty, black deposit. If allowed to build to excessive amounts, this deposit can interfere with uniform primer seating and thus cause inaccuracy. A high primer can also be a potential hazard. This deposit is easily removed with a few twists of a primer pocket cleaner. Great for handloaders.

Cylcone Rotary Tumbler

Item #7631550

3. Case Cleaning Equipment

A dull looking case is of no consequence. A dirty case, however, may reduce reloading quality and keep a defect from being noticed or scratch reloading dies and/or chambers requiring premature die/firearm replacement.

Cases can be cleaned in a number of ways. Case tumblers, either vibratory or rotary can make some mighty dirty brass look like new. Case tumblers are available to fit almost every need with respect to the quantity of cases to be processed and cost. Ultrasonic cleaners also do a great job and will clean out primer pockets as well as the inside of the case.

Turbo Sonic 2500

Item #7631700

Turbo 1200 Pro Tumbler

Item #7631318

Scale check weight sets

Item #7752313

4. Scale Check Weight Sets

A reloading tool that keeps your scale honest.Scales are delicate instruments. Should a scale be inadvertently subjected to some undue rough handling, a scale check weight set can help determine if the scale’s accuracy has been compromised.

All-American 8 Press

Item #7040750

5. Turret Presses

Turret presses have multiple die stations. The advantage is that a reloader can place a case into the shell holder and fully load it, by rotating each die into position. This speeds up loading and is a method sometimes favored by handgun cartridge reloaders.

Turret presses also allow the reloader who loads cases by the preferred batch method (performing the same operation on all of the cases to be loaded before moving on to the next step) to set up all the dies and leave them in position on the press. This eliminates the need to repeatedly remove and replace dies. Lyman's improved and versatile Turret presses allows smooth indexing while maintaining rock solid turret support.

Flashhole Uniformer

Item #7777760

6. Flashhole Uniformer

This little handheld reamer will remove the burr at the terminus of the flash hole. This is an accessory that originally saw use with serious bench rest shooters. Today, in their search for accuracy many handloaders feel it worthwhile to deburr flash holes.

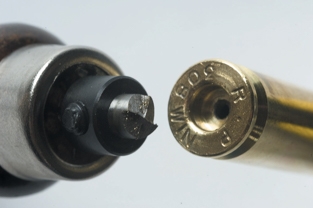

Primer Pocket Reamer

Item #7777785

7. Primer Pocket Reamer

Primer pocket reamers are required to remove the crimped material from military style cases. Such cases have the primer locked into place by an impact-shifting of case head brass around the end of the primer pocket. It is best to use a special heavy-duty decapping rod assembly to remove crimped in-place primers. After removing fired primers from such cases, a new primer cannot be safely or correctly seated until a reamer is used to remove the crimped material. The Primer Pocket Reamer by Lyman is essential for removing military crimps.

Primer Pocket Uniformer

Item #7810215

8. Primer Pocket Uniformer

A primer pocket uniformer is used by many shooters to ensure that the bottom of every primer pocket is flat, which ensures that every primers is seated to a uniform depth. The benefits of this additional effort however may not be noticed unless reloading for a very accurate rifle. The Primer Pocket Uniformer by Lyman allows reloaders to ensure a uniform primer depth for more consistent ignition and improved accuracy.

Gen 6

Item #7750550

9. Automatic Electronic Powder Scale

While not inexpensive, this accessory can simplify the process of powder charge weighing and improve accuracy on powder measurements. At a push of a button the electronic scale automatically feeds powder onto the scale pan, first at a fast rate and then at a greatly slower rate to bring the scale into balance. Once started it is a hands-off operation.

As time goes by, the reloader will find that the list of other available accessories appears near endless. Let real needs or personal goals dictate which ones should be on your loading bench.

Getting started requires only the previously discussed sixteen basic items. Indeed, one could happily load hundreds-of-thousands of rounds with only a few additional accessories - a powder measure and primer pocket cleaner being the most likely candidates. From this point on, it should be obvious when you will actually benefit from an addition to your basic tools. Lacking an obvious need, chances are you will get along nicely without further additions.